Electronic / Semiconductor

SMD component counting machine

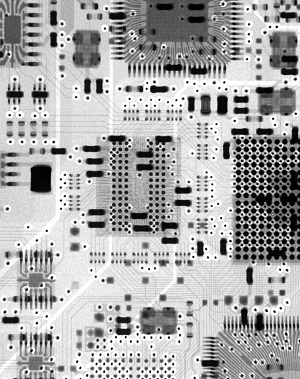

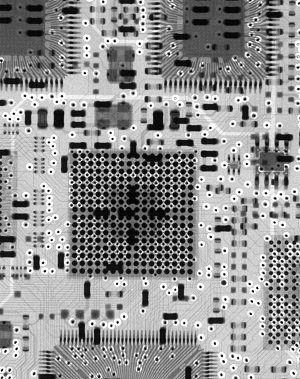

Printed Circuit Board, PCB

Surface-mount technology,SMT

ball grid array (BGA)

INDUSTRIAL INSPECTION

Applications

Nanoray Co. has X-Ray energy spectroscopy technology, widely used in electronic / semiconductor, energy / material, food / pharma, academic / project.

Technical capabilities synchronize to international standards, and there is radiation safety certification.

Technical capabilities synchronize to international standards, and there is radiation safety certification.